Ordering 3D Printed Parts Online: A Modern Manufacturing Solution

- Kristaps Rozenbergs

- Apr 8, 2025

- 5 min read

Updated: Apr 27, 2025

In today's rapidly evolving design and manufacturing world, getting custom parts made quickly and affordably is easier than ever, thanks to online 3D printing services. Whether you're developing a prototype, producing small batches, or working on a personal project, 3D printing offers a simple and flexible way to create custom parts—without needing your own equipment.

In this article, we’ll look at the benefits of ordering 3D printed parts online, where you can get them made, and what is the difference between 3D printing and CNC machining.

Why Order 3D Printed Parts Online?

What are the benefits of ordering 3D printed parts online?

Ordering 3D printed parts online is convenient, fast, and provides access to a wide range of materials and technologies that many individuals or small businesses cannot afford.

Online 3D printing services have changed how prototypes and parts are made, making it simpler to turn ideas into reality.

Here are some key benefits of using these services:

1. Accessibility of 3D Printing Services

One of the main benefits of online 3D printing services is their accessibility.

3D printing services connect users with industrial-grade 3D printers and high-quality materials, removing the need for costly investments in equipment and facilities. This makes advanced printing technology available to hobbyists, startups, and small businesses that previously could only access it through large corporations.

Users can choose from various printing technologies, such as FDM, SLA, and SLS, based on their specific needs, without the extra costs of owning and maintaining the machinery.

2. Speed and Quick Turnaround Times

In today’s fast-moving market, speed is crucial.

Many online 3D printing services are great at providing quick turnaround times.

Thanks to advanced production techniques and efficient workflows, these services can often deliver high-quality parts in just a few days. This rapid response helps businesses speed up their product development cycles.

With faster delivery, companies can quickly test and adjust their designs without the long delays usually found in traditional manufacturing. This ability to get parts quickly is vital for businesses that need to meet tight deadlines or take advantage of market opportunities as they come up.

3. Easy Customization of 3D Printed Parts

One major advantage of ordering 3D printed parts online is the high level of customization available. Many services let you upload your own CAD files, allowing you to set specific dimensions, tolerances, and finishes for your project. This is especially useful for designers and engineers who need custom components that meet precise requirements.

Customizing parts improves the functionality of the final product and enables innovative designs that can help a business stand out in a competitive market. Additionally, some services offer design assistance to help users refine their ideas before printing, further enhancing the customization experience.

4. Scalability (Handling Different Order Sizes)

One major benefit of using online 3D printing services is scalability.

These services can easily handle different order sizes, whether you need a single prototype or a small batch of parts.

This flexibility allows businesses to adjust their production based on demand without needing large manufacturing setups. For startups and small businesses, this means they can quickly respond to market needs and change their production quantities without extra costs. Additionally, many online services offer tiered pricing, making it affordable to produce small batches. This enables companies to test their products before committing to larger production runs.

In conclusion, the ability to order 3D printed parts online provides significant advantages that cater to the needs of individuals and small businesses alike. With enhanced accessibility, rapid production speeds, extensive customization options, and scalable solutions, these services are transforming the landscape of manufacturing and product development, making it more efficient and accessible than ever before.

Where to Order 3D Printed Parts Online?

If you're looking for a reliable and cost-effective way to get custom parts made, Perfecttio is your go-to solution.

We offer on-demand 3D printing services tailored for both prototyping and production (including small-batch production).

Whether you need a few units or a production run, we provide high-quality results with quick turnaround times. Perfecttio also specializes in custom 3D printed parts—ideal for cases where original components are too expensive or no longer manufactured, such as for older or discontinued machines.

Wondering how to order 3D printed parts? With our flexible 3D printing service and expert support, the process is simple. Ordering 3D printed parts online has never been easier or more efficient.

Ready to get started? Contact us for a quote.

Why Choose 3D Printing Over CNC Machining?

CNC machining is still important for precision and high-volume manufacturing, but 3D printing offers clear advantages for prototypes and small production runs.

Additive manufacturing (including 3D printing) has changed the way products are made, making it easier to create complex shapes and test designs quickly. Today, ordering 3D printed parts online lets individuals and businesses access these benefits without needing their own machines or large budgets.

Learn more:

1. Design Freedom of 3D Printing

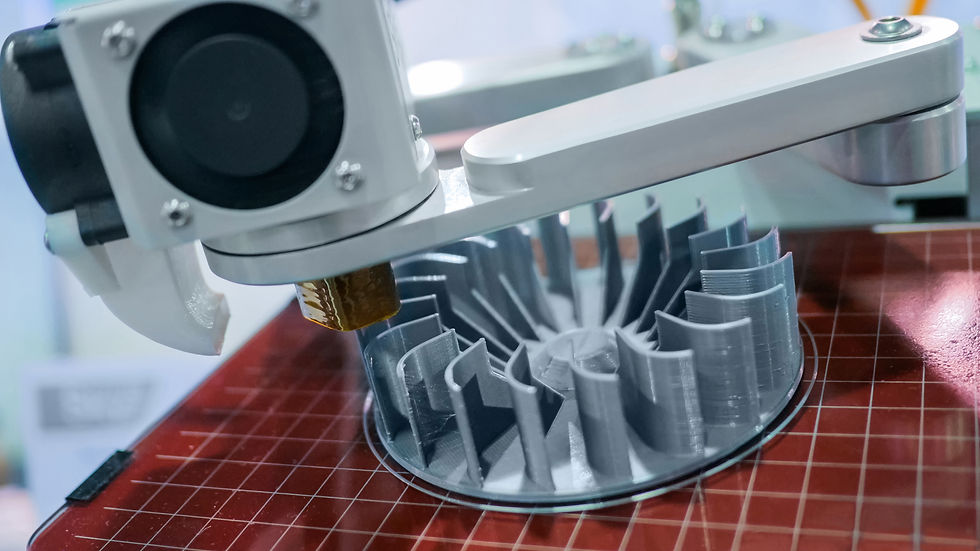

One of the most significant benefits of 3D printing is its ability to provide exceptional design freedom. Unlike traditional subtractive manufacturing techniques, which often involve cutting away material from a solid block to create the desired shape, 3D printing allows for the creation of intricate and complex geometries that are difficult or impossible to achieve with conventional methods.

This capability opens up new avenues for innovation, enabling designers to experiment with organic shapes, internal structures, and lightweight designs that optimize performance while minimizing material use. For instance, lattice structures can be printed that offer high strength-to-weight ratios, making them ideal for aerospace and automotive applications.

2. Lower Setup Costs

Another cool benefit of 3D printing is the significantly lower setup costs associated with the process. In contrast to CNC machining, which often requires extensive tooling, fixtures, and setup for each individual part, 3D printing streamlines the production process by relying solely on a digital file. This means that once a design is finalized, it can be easily replicated without the need for additional investments in tooling or machinery.

As a result, businesses can save considerable amounts of money, particularly for small batches or one-off prototypes, making 3D printing a cost-effective solution for startups and smaller manufacturers.

3. Rapid Iteration

The speed at which design iterations can be realized is another notable advantage of 3D printing technology. In traditional manufacturing, making design changes often involves lengthy lead times, retooling, and additional costs associated with setting up new production processes.

However, with 3D printing, it is easy to make quick design changes and print new versions almost immediately. This rapid iteration capability allows teams to test and refine their designs in real-time, facilitating a more agile development process that can significantly shorten the time to market for new products. This is particularly valuable in fast-paced industries where staying ahead of competitors is crucial.

4. Material Efficiency in 3D Printing

3D printing is more efficient in using materials compared to traditional manufacturing methods.

It creates objects layer by layer, which means that material is only applied where it's needed, resulting in much less waste. On the other hand, traditional methods often waste a lot of material by cutting away excess from a larger piece. This not only harms the environment but also increases production costs. By reducing waste, 3D printing supports sustainability and makes manufacturing more cost-effective.

Learn more: How Strong Are 3D Printed Parts?

5. No Minimum Quantity

Lastly, the flexibility of production quantities is a key advantage of 3D printing.

Many CNC shops impose minimum order requirements to justify the costs of tooling and setup, which can be a barrier for small businesses or individuals needing only a few parts. In contrast, 3D printing services typically do not have such minimum order quantities, allowing for the production of single items or small batches without incurring prohibitive costs. This flexibility makes 3D printing an ideal choice for custom projects, limited-edition runs, or experimental designs where demand is uncertain.

Whether you're prototyping or ready for production, our team is here to help you bring your ideas to life with precision and performance. Contact us for more information!

.png)

Comments